SALIENT FEATURES

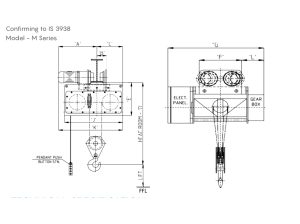

Design: “GLOBE” Electric Wire Rope Hoist are designed as per IS: 3938-1983 and are suitable for Medium & Heavy duty applications.

Construction: “GLOBE” Hoist has a unique modular construction which makes them an ideal choice since each sub assembly is easily accessible individually, thus reducing the time and cost involved in the maintenance.

Frame: The main plates of tested quality steel are welded / bolted to form very rugged frame.

Rope Drum: Rope Drum is fabricated out of mild steel or seamless tube and is machined and grooved in accordance with IS: 3938 to accommodate full length of wire rope in one layer.

Gear Box: Totally enclosed, Immersed oil bath lubricated gear box houses the gear machined out of EN-9/EN-24 Steel and teethed on precision hobbing machines.

Motors: Hoist duty 415 V. 50 Hz, 3 PH. A.C., Squirrel cage Induction motors with 40% CDF, 150 Starts / Hr ‘B’ class insulation and of ample rating and standard make like NGEF / CGL / BHARAT BIJLEE etc. are used.

Hook: Conforming to IS: 8610. Free to rotate and swivel.

Brake: Instant action ‘Fail to Safe’ Electro Magnetic D.C Disc Type to ensure maximum safety and reliability in operation.

Wire Rope: 6 x 37 construction, FMC, best plough steel tested wire rope as per IS: 2266 is used of reputed make like Usha Martin / Mahadev etc.

Limit Switch: Snap action limits switch to prevent over hoisting and over lowering is provided for maximum safety, make BCH / Jai Bala Ji / STS / T.C.

Panel: Totally enclosed dust and vermin proof-housing components of standard makes like ‘SIEMENS, ABB, SCHNEIDER ELECTRIC, provides control at low voltage for safety of operator.

Control: From push button pendent station supported with steel Wire Rope, operating at 110 Volt.

Technical Specification:

| Model | GWRH | GWRHM1-82 | GWRHM1-84 | GWRH | GWRHM2-84 | GWRH | GWRH M3-104 | GWRH M3-124 | GWRH | GWRH | GWRH M5-184 | ||

| M0-82 | M2-82 | M2-104 | M4-144 | M5-144 | |||||||||

| Capacity | TON | 0.5 | 1 | 2 | 2 | 3 | 5 | 5 | 7.5 | 10 | 10 | 15 | |

| Standard lifting height | MM | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Hoisting speed | MPM | 6 | 6 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Hoisting motor | K.W | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 7.5 | 7.5 | 11 | |

| Traversing speed | MPM | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

| Traversing Motor | K.W | 0.18 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1.1 | |

| Motor Specifications | 40 % CDF, 150 Starts/Hr, 50 Hz, 415V, 3 Phase, AC, Squirrel cage Induction Motor, IE2. | ||||||||||||

| No. of falls (Rope) | Nos. | 2 | 2 | 4 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Rope Diameter | MM | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 12 | 14 | 14 | 18 | |

| Rope Construction | 6 x 36 / 37, Fibre Core (FMC) /1770 N/MM Sq., Ungalvanised, Breaking Strength – 40KN. | ||||||||||||

| A | MM | 385 | 425 | 425 | 480 | 480 | 480 | – | – | – | – | – | |

| B | MM | 115 | 125 | 125 | 150 | 150 | 150 | – | – | – | – | – | |

| C | MM | 200 | 290 | 300 | 360 | 360 | 360 | 415 | 415 | 500 | 500 | – | |

| D | MM | 700 | 750 | 920 | 950 | 1000 | 1100 | 1200 | 1250 | 1400 | 1400 | – | |

| E | MM | 300 | 380 | 380 | 460 | 460 | 460 | 585 | 585 | 655 | 655 | – | |

| Dimensions | F | MM | 300 | 380 | 380 | 400 | 400 | 400 | 580 | 580 | 580 | 580 | – |

| G | MM | 720 | 830 | 1050 | 1040 | 1040 | 1040 | 1090 | 1090 | 1200 | 1200 | – | |

| L | MM | 265 | 260 | 260 | 375 | 375 | 375 | 280 | 280 | 315 | 315 | – | |

| H | MM | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | – | |

| J | MM | 390 | 530 | 530 | 720 | 720 | 720 | 830 | 830 | 1000 | 1000 | – | |

| K | MM | 600 | 740 | 750 | 840 | 840 | 840 | – | – | – | – | – | |

| Recommended ISMB | MM | 150 x 75 to | 200 x 100 to | 250 x 125 to | 300 x 140 to | ||||||||

| Sizes | 200 x 100 | 350 x 140 | 450 x 150 | 600 x 210 | |||||||||

| Net Weight | KG | 160 | 216 | 240 | 400 | 460 | 540 | 800 | 900 | 1200 | 1250 | 1400 | |

| Note:- Due to continuous development and improvement specifications listed above may be changed without notice. | |||||||||||||