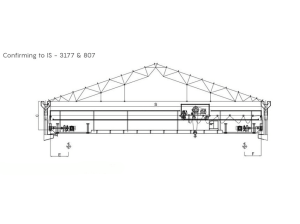

Confirming to IS 807-1976, IS 3177-1977 or IS 4137-1985.

RANGE:

We manufacture Double Girder overhead Travelling cranes ranging from 0.5 Ton to more than 100 Tons. We have comprehensive range of heavy duty EOT Crane Systems (D.G, S.G, Under Slung, Gantry / Goliath Cranes etc.) for various applications in steel, power, construction, sugar, heavy and General Engineering Sectors etc. Every crane is designed and manufactured as per customer requirement keeping in consideration with lot of things so as to provide best solution for their need and manufacture an optimum.

SALIENT FEATURES:

Box Girder: Girders are of plate box type construction with butt-welding joints in tension zone radio graphed areas.

Gear Box: Totally enclosed oil splash lubricated gear box with precision machine cut gears pinions.

Wheel Assemblies: C.T & L.T both assemblies are provided on “L” Block Type bearing housing fitted with anti friction spherical roller bearings.

Rope Drums: Seamless / fabricated rope drum suitable for required height of lift having flanges at both ends, accurately grooved as per desired pitch of wire rope. Mounted on spherical roller bearings fitted with a bearing housing at both ends.

Wire Rope: Fiber/steel core wire rope having 6 x 36 / 37 construction suitably selected tensile strength and factor of safety.

Mantenance Platforms: full length walkway platform on one end and two short platform on the other end with suitable height hand railing which ensures full safety for the maintenance.

Couplings & Brake Drums: C.T & L.T both assemblies are provided on “L” Block Type bearing housing fitted with anti friction spherical roller bearings.

Electrical Motors: All motors are S4 Crane Duty fan cooled standard motors with suitable rating as per relevant standards and classification of cranes. Invertor duty / slippring motors are also used as per site & design requirements.

Braking System: Electro hydraulic thrustor / D.C Shoe / A.C shoe type brakes are used for various applications of EOT Cranes. Individual brake for each motor is provided with designed & required braking torque as per classification of crane.

Control Panels: Steel sheet housed, powder coated control panel loaded with complete control switchgears along with control transformer. All control panels are as per IP 55 Protection.

Safety Parameters: Rotary type limit switch for main Hoist & Long lever type Limit switches for cross & long Travel motion are provided, Neoperene / Spring buffers are provided for C.T & L.T Motions, full length walkway platforms, maintenance platforms & 110 V Pendent supply voltage makes our crane fail safe.

UNIQUE FEATURES:

• State-of-the-art designs confirms to Indian and International Standards.

• Easy to commission, having maximum rigidity with a minimum dead load

• Safe and reliable hoisting and travelling

• Girders are cambered to an account equal to the deflection caused by dead load and half the live load of trolley

• Full length platforms on one side two short on other side for ease of maintenance

• Micro speed will be attained through (VFD) Drives

• Steel Core hoist rope having minimum factor of safety of 6

• Safety and better productivity are ensured with advanced automation option

• Safe and substantial production of cranes in compliance with ISO 9001

• Higher efficiency to save power

• All motions are protected with limit switches

VARIANTS:

• Double girders overhead travelling cranes

• Single girder overhead travelling cranes

• Grabbing Cranes

• Ladle Cranes

• Goliath / Semi Goliath Cranes

• Single Girder / Double Girder Under slung cranes

APPLICATION AREAS:

Steel mills, Foundries, Plastic Moulding Plants, Paper plants, Cement plants, Power plants, Dairy plants, Chemical plants Fertilizer plants, Petrochemical plants, Engineering Industries, Textile industries, General Applications, CNC / VMC Machine workshops, etc.

| TECHNICAL SPECIFICATIONS | |||||||||||

| Model | SWL M.T | Span (mtrs) ‘S’ | HeadRoom (mm) ‘C’ | End Clearance (mm) ‘A’ | Hook approaches (mm) (mm) ‘E’ ‘F’ |

Wheel Base (mm) ‘W’ | Girder Projection Below Rail (mm) ‘B’ | Crane Width (mm) | Wheel Load (Approx) (MT) | Crane Wt.(Approx) MT | |

| GDG-5 | 5 | 10 15 22 |

1500 1600 1800 |

200 200 225 |

900 900 1000 |

750 750 800 |

3000 3000 4400 |

200 250 350 |

3700 3700 5200 |

5.6 6.0 7.4 |

9.4 11.6 16.0 |

| GDG-7.5 | 7.5 | 10 15 22 |

1600 1700 1900 |

200 225 250 |

900 900 1000 |

750 750 800 |

3000 3200 4400 |

250 300 400 |

3700 4000 5200 |

7.5 8.0 9.9 |

11.4 12.6 18.4 |

| GDG-10 | 10 | 10 15 22 |

1700 1800 1900 |

250 250 250 |

900 1000 1000 |

750 800 800 |

3200 3400 4400 |

300 350 400 |

4000 4200 5200 |

9.5 10.1 11.7 |

13.8 15.5 21.5 |

| GDG-15 | 15 | 15 22 |

2000 2200 |

250 250 |

1100 1200 |

900 1000 |

3800 4400 |

400 450 |

4600 5200 |

14.3 16.5 |

18.8 27.2 |

| GDG-20 | 20 | 15 22 |

2100 2300 |

300 300 |

1100 1250 |

900 1050 |

4200 4500 |

400 450 |

5300 5800 |

16.9 19.2 |

20.4 28.4 |

| GDG-25 | 25 | 15 22 |

2350 2500 |

300 300 |

1100 1250 |

900 1050 |

4200 4500 |

400 450 |

5300 5800 |

20.8 23.1 |

22.8 32.5 |

| GDG-30 | 30 | 15 22 |

2500 2700 |

300 300 |

1200 1300 |

1000 1100 |

4200 4600 |

450 500 |

5400 6000 |

23.6 26.6 |

25.5 37.5 |

| GDG-40 | 40 | 15 22 |

2900 3100 |

300 300 |

1300 1400 |

1100 1200 |

5100 5200 |

500 50 |

6500 6600 |

28.6 33.2 |

25.5 43.0 |

| GDG-50 | 50 | 15 22 |

3200 3300 |

300 300 |

1500 1500 |

1300 1300 |

5400 5500 |

50 600 |

7000 7500 |

36.8 40.6 |

34.6 49.5 |

| GDG-60 | 60 | 18 22 |

3800 4000 |

300 300 |

1600 1600 |

1200 1200 |

5600 5800 |

600 650 |

7000 7500 |

49.0 52.0 |

55.0 70.0 |

| GDG-80 | 80 | 15 22 |

4000 4200 |

300 300 |

1900 1950 |

1300 1350 |

5800 6000 |

650 700 |

7200 7500 |

52.0 53.5 |

75.0 90.0 |

| GDG-100 | 100 | 15 22 |

4200 4500 |

300 300 |

1900 1950 |

1400 1400 |

6000 6200 |

700 750 |

7500 7800 |

58.0 61.0 |

90.0 100.0 |